PROPULSION

Rolls' Boeing 787/Airbus A330neo Durability Upgrade Nears End Goal

> TURBINE LIFE LIMITS TO BE LIFTED > CERTIFICATION ON 787 IS EXPECTED WITHIN MONTHS

Guy Norris,

May 5, 2025

Rolls' Boeing 787/Airbus A330neo Durability Upgrade Nears End Goal

PROPULSION

> TURBINE LIFE LIMITS TO BE LIFTED > CERTIFICATION ON 787 IS EXPECTED WITHIN MONTHS

Guy Norris

London

Rolls-Royce’s long-running campaign to improve the time on wing of two key engines—the Trent 7000 on the Airbus A330neo and its sister Trent 1000 TEN on the Boeing 787—is entering its final phase with the start of tests on a second set of durability enhancements.

Designed to boost time on wing by a further 30%, the second package follows an initial set of upgrades that doubled time on wing for the Trent 7000powered Airbus since its introduction in late 2022. The same basic upgrade package now flying on the A330neo recently completed flight tests with Boeing and is expected to be certified for the 787 in the coming months.

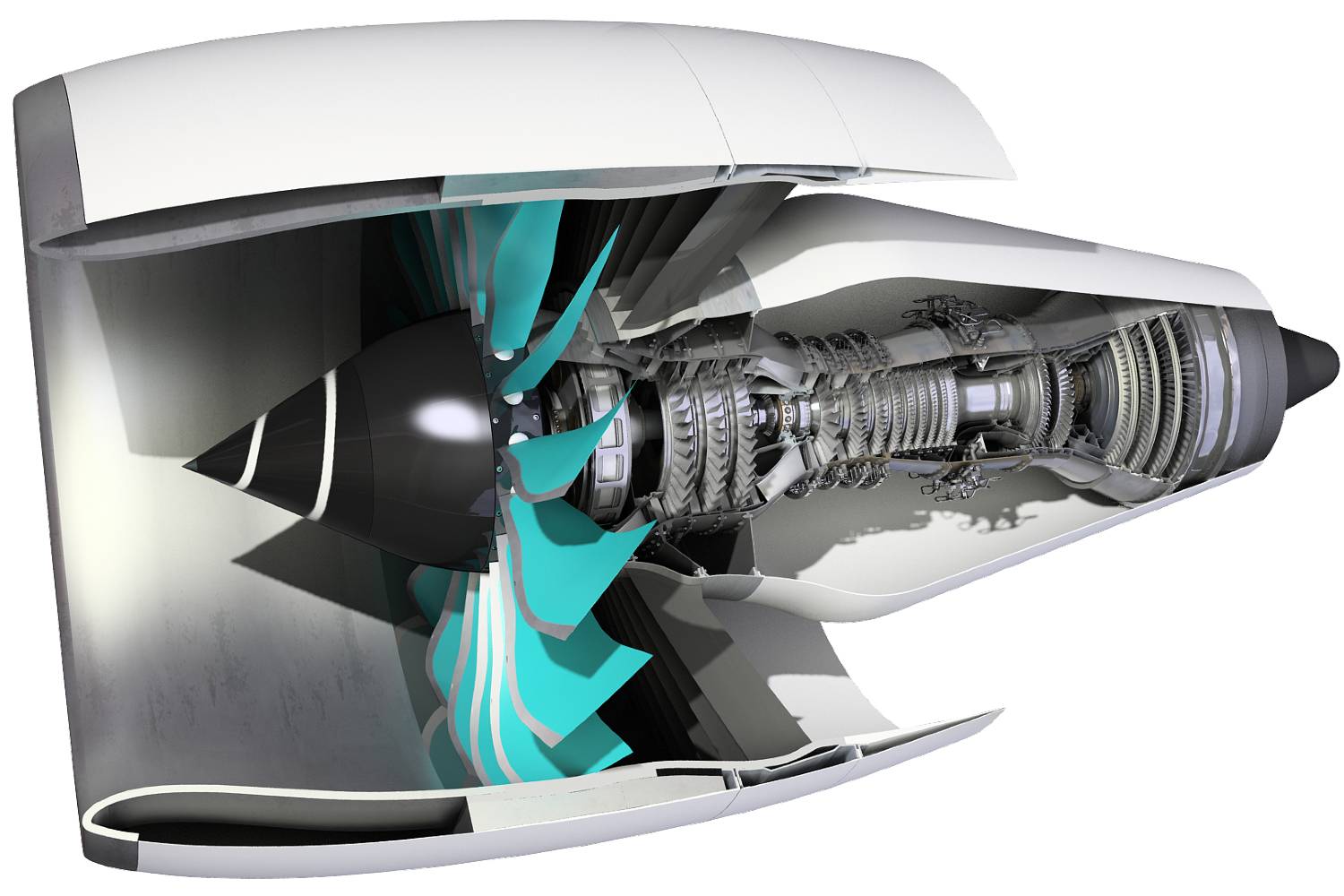

Dubbed the Durability Enhancement (DE) packages Phase 1 and 2, the upgrades focus on increasing the resilience of the high-pressure (HP) turbine blade and its associated hot-section components (see graphic on facing page). The earlier design proved vulnerable to wear and cracking, leading to mandated life limits and frequent inspections—shortcomings that have affected operators and proven damaging to Rolls in terms of cost, reputation and market share on the 787.

Prior to the introduction of Phase 1, Trent 7000s were being removed from A330neos at 1,000 flight cycles. “We’re now getting to 2,000 [cycles] and will be at 2,500 as we work our way through the rest of this year, so that’s more than double the time on wing,” Trent 7000 Chief Engineer Paul Sixsmith says. “That just means the engines are out there for so much longer. Operators are not having to do engine removals. We’re not having to induct engines into our shops, so it’s a virtuous cycle.”

TRENT 1000 TEN Durability Enhancement Packages

Phase 1

1 New high-pressure turbine blade with increased flow and optimized aerofoil and shroud film cooling

2 New combustor rear inner case to deliver the increased high-pressure turbine blade cooling flow

3 New fuel spray nozzle with a conical cut back to reduce smoke emissions

4 Full-authority digital engine control software change

Phase 2

5 New advanced coatings on combustor tiles for hot and sandy environments

6 High-pressure nozzle guide vane film cooling changes and coating optimization

7 High-pressure turbine blade shroud weight reduction and blade coating optimization

8 Trent XWB-84-style design improvements to the combustor/high-pressure nozzle interface for reduced wear

Source: Rolls-Royce

The improvements have been hardwon and cannot come quickly enough for Rolls. “The position we’re in today is not acceptable for us,” Sixsmith says. “It’s clearly unpalatable for our customers, and it means that we must do more shop visits. Considering where we are operationally, as we get out of that situation, it all starts to flow when we are more than doubling that time on wing.”

For the 787, on which Rolls competes with GE Aerospace’s GEnx-lB, the move is critical to the company’s battle to regain dwindling market share. “It just restores confidence back into those Trent 1000 operators today, as well as future people that want to buy the jet and the Trent 1000 TEN,” Sixsmith says. “Clearly, with Boeing as well, it is important to show that we can do it, and this makes us truly competitive with the other guys.”

The new HP turbine blade at the heart of the Phase 1 package features a 40% increase in shroud film cooling airflow, with added cooling holes in the midchord section and an enlarged hole in the root for higher flow from a redesigned combustor rear inner case. Supporting modifications include revisions to the engine control software for an updated combustor light-up pattern and turbine gas temperature trim, which is a parameter used to adjust the fuel control unit for setting idle RPM and maximum speed for the engine pressure ratio. The new fuel spray nozzle is designed to reduce smoke emissions and offset revisions to the combustor rear inner case.

In parallel to introducing the upgrade into the A330neo fleet, Rolls has conducted a series of engine tests simulating more than 3,000 cycles—or more than five years of continuous in-service operation—with the Phase 1 package.

“We’ve now just completed this additional cyclic test and inspected the parts, and with that—in combination with our other fleet understanding— we’ve got to the point where we’re starting to release more and more life on that blade,” Sixsmith says. “I’ve got bench data that supports where I want to go.”

As many of the initial operators with DE Phase 1 packages fly their aircraft on high-cycle, low-hour flights, the first upgraded Trent 7000s are coming in for shop visits. “We’ve taken out the blades, and I’m more than happy for them to run for another 1,000 or 2,000 cycles, as they’re in a great condition,” Sixsmith says.

Having released the HP turbine blade life to 2,500 cycles, he says, “as we progress through this year and early next year, we’re actually going to completely remove that limit.” At that point, the engine will switch to an on-condition maintenance and inspection protocol, bringing it into line with other members of the Trent family.

Now the focus is on testing the second enhancement package, which Rolls hopes will form the basis for a finalized build standard for both Trent 1000 TENs and 7000s starting in 2026. “Package Two is the next generation, because we’re starting to go again,” Sixsmith says. “My intention is that as we get to the end of 2025 and enter into 2026, the DE Phase 2 modification package will overtake DE Phase 1 and it will be certified and released as a package that builds on DE Phase 1.”

The second package incorporates an advanced calcium-magnesiumalumino-silicate-resistant coating on the combustor tiles for hot and sandy environments, as well as changes to the film cooling on the HP nozzle guide vanes (see graphic on page 51). Also included are Trent XWB-84-style design improvements to the combustor/ HP nozzle interface for reduced wear and a redesigned, lighter-weight HP turbine blade shroud.

“Package Two makes a series of discrete changes to some of the hot-end statics and the blade itself, and some very minor changes to the combustor for durability purposes,” Sixsmith says. “We’re taking some parasitic weight out of the blade shroud, using electrical discharge machining to take out small amounts of material to reduce mass.”

As stress is a function of speed squared, a weight decrease will result in lighter loads on the blade. “Therefore, the stress on all the features is dramatically reduced as well,” he notes. “On the static components, we’re redistributing the air, and we’re changing the way we mount it as well in the system. So we’re taking some experience from our other engines and reading that across to how we locate the system and hold it in place within the engine.”

Type testing on the first engine with the DE Phase 2 package, meanwhile, is underway at Rolls’ facility in Derby, England, and is expected to continue through May. A second engine destined for dedicated endurance testing is also in build and will follow in the next few months.

“Because we’re targeting how we want to exercise some of those components, we’re picking a cycle that goes after the static parts,” he says.

DE Phase 2 testing will include a “one-shot” thermal paint test—an evaluation also conducted on DE Phase 1. “It’s called one-shot because you’ve got one go at getting it right,” Sixsmith explains. Upgraded components are coated in a special paint with temperature capabilities spanning 220-1,350C, and typically have five or more change points. During a prescribed test cycle, the paints change color irreversibly with temperature, providing a complete surface temperature record that can be compared with modeling predictions.

Testing is largely expected to be completed by midyear, although some may extend into the early part of the third quarter. “We’re targeting for all our certification documentation to be in place so we can bring all that together for the end of this year,” Sixsmith says, adding that the scope of the second package will not require the same level of certification as the initial upgrade.

“We were very careful on Durability Enhancement Package 2 that we didn’t find ourselves having to do certification work that went above and beyond the threshold for the next level of integration and oversight that you need to do either at engine level or regulator aircraft level,” Sixsmith says. “The changes that we’ve introduced are enhancements that we are able to certify with minimal additional work.”

With tests underway, Rolls is also working with the supply chain to ensure readiness for industrializing the changes and introducing them into the production line as well as for retrofit during maintenance, repair and overhaul. The company aims to release the modification in full for production by the second quarter of 2026.

“We’re now in a position that about 75% of the flying fleet [with more than 150 A330neos in service] has been rolled to the DE 1 package,” Sixsmith says. This has been through newproduction engines delivered starting in September 2022 as well as earlier ones coming through maintenance, repair and overhaul shops. Some early engines will never see the Phase 1 package and will go straight to Phase 2 on their next shop visits, he notes.

Sixsmith says he “sees the daylight” now at the end of Rolls’ long running campaign to bring the same upgrades to the Trent 1000 TEN on the 787. Plans to pursue approval on the 787 have been frustrated by the slowdown in new certification activity at Boeing amid heightened regulatory scrutiny following the 737 MAX accidents as well as other safety and quality missteps. The resulting backlog of certification delays with the 737-7 and -10 and 777X programs has had a knock-on effect on Boeing’s ability to flight-test the engine upgrade. This work was Anally completed in January.

“We’re counting the weeks and months now to get the formal FAA certification release,” Sixsmith says. “We’re working the final few reports through with Boeing, and we are on track to get that out to our customers, certainly, in the next few months.”

The DE Phase 2 modification on test in Derby has the same bill of material for both engines. “The certification plan that goes with that is actually two pieces of standardization—one that will go to Boeing for the read across to the 787 and one that goes to Airbus for the A330neo as well,” he says. “It’s exactly the same modification, and we’re driving them at exactly the same pace. Our desire is that the solution arrives at the same time with a service bulletin for both the Trent 7000 and Trent 1000TEN in 2026.”

By then, Rolls also aims to realign the supply chain. “By the end of 2026, I only want to be producing one standard of material,” Sixsmith adds.